EOSS®

Coating platform EOSS® – A tool for the development of precision optical filter systems

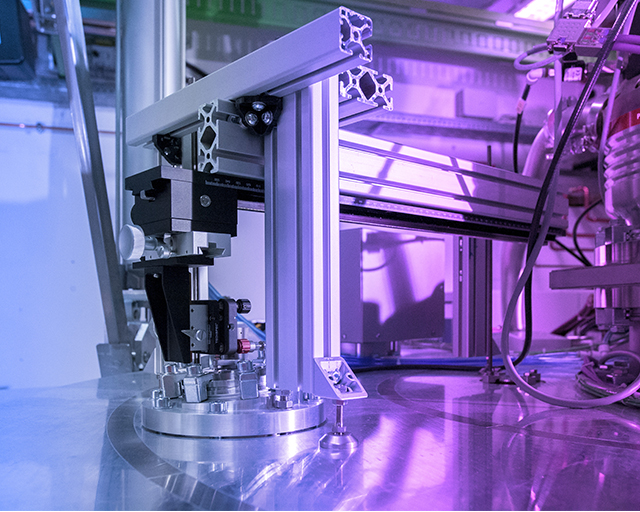

With the EOSS® (Enhanced Optical Sputtering System) coating platform developed by the Fraunhofer Institute for Surface Engineering and Thin Films IST, highly sophisticated optical coatings can be produced, e.g. for optical filters. In addition to almost defect-free layers, complicated layer designs comprised of up to several hundred individual layers can be realized in a controlled manner with very high precision and uniformity.

The Fraunhofer IST's industry-typical turntable system can hold up to 10 substrates with a respective diameter of 200 mm. The individual layers are applied to the substrate in up to three chambers by means of magnetron sputtering. Optimized sputtering targets in the form of cylindrical tubes, so-called rotatable cathodes, are utilized. A special trick for reducing the contamination of the layer with particles is the “sputter-up” concept: the coating is applied from bottom to top, so that heavier particles cannot condense on the substrates. The implementation of the monitoring system MOCCA+® (Modular Optical Coating Control Application), which was specifically developed at the Fraunhofer IST, enables not only a precise control of the layer thickness but also an automation of the coating process. In this way, optical filter coatings are produced which exhibit a very high quality for both the layer and the specifications.

One example is presented by the optical beam splitters with very steep edges developed at the Fraunhofer IST within the framework of a project funded by the BMBF. These are used, for example, for digital exposure devices in the printed circuit board industry. The aim was to increase the laser power by utilizing edge filters. In order to couple as many laser diodes as possible without loss, the filters must generate a coherent laser beam within a very narrow spectral range. This is achieved by means of a dielectric multi-layer coating in which one high-refractive and one low-refractive material, in the form of thin layers, are stacked on top of each other in such a way that the end result is a spectral range of high reflection and high transmission respectively. The edge, i.e. the transition range between high reflection and high transmission, thereby becomes steeper as more layers are applied. In the present example, layer systems with, in some cases, more than 100 individual layers and a total layer thickness of more than 15 µm were produced.

Last modified: