Magnetron sputtering

For the economical deposition of functional coatings from semiconductor technology through to medical products, magnetron sputtering delivers coatings of the highest quality

The Fraunhofer IST brings together unique expertise in the industrial use of magnetron sputtering. From applications for friction reduction or protection against corrosion and wear, through electrical and optical functions, and on to medical technology, the different variants of magnetron sputtering are utilized. Diverse coating sources, as well as process monitoring and active control, are applied and further developed at the Fraunhofer IST.

Application-oriented development on industrial coating facilities

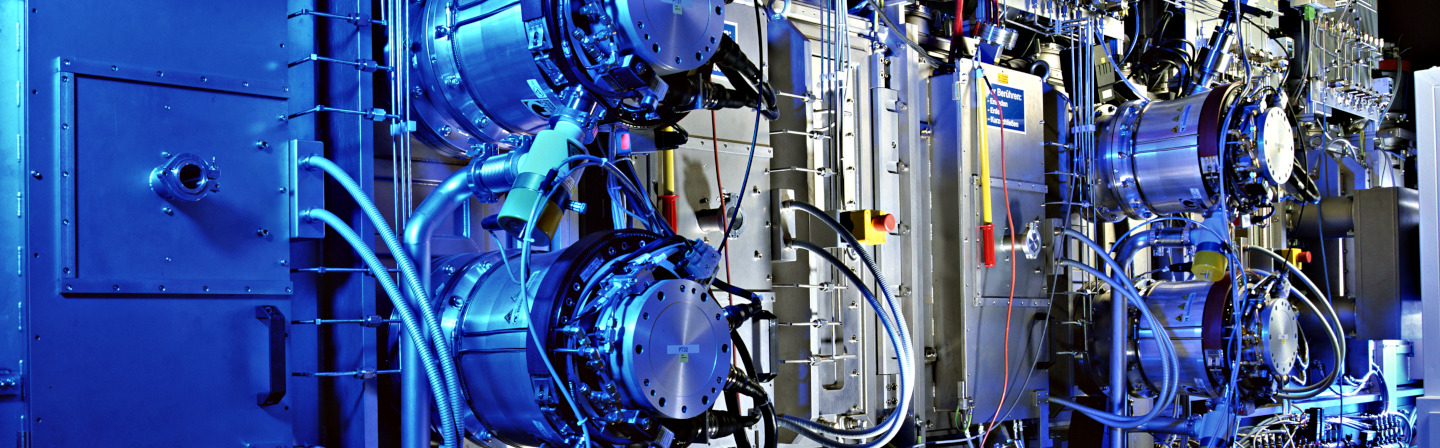

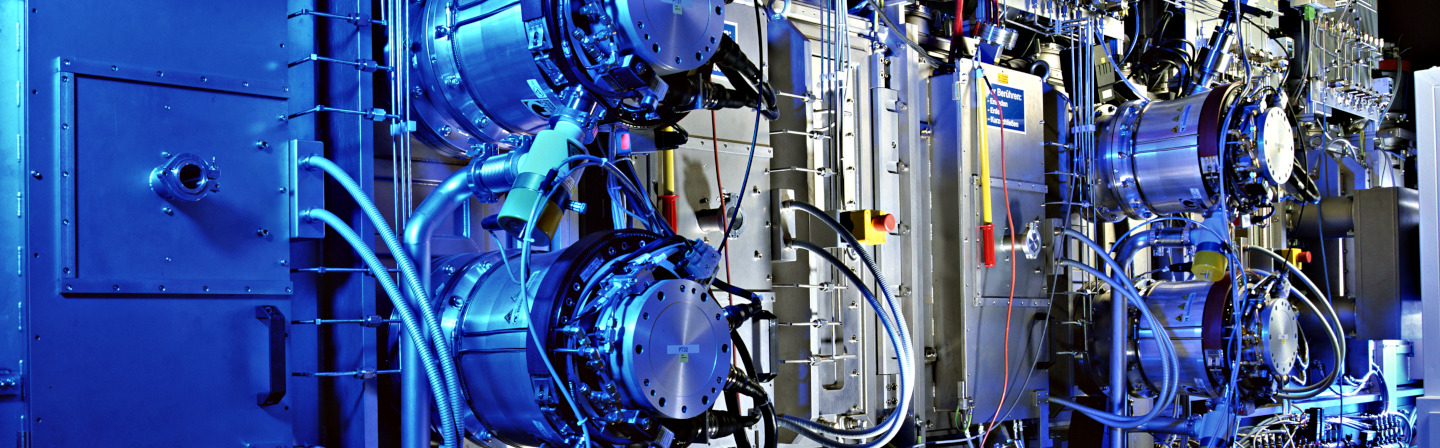

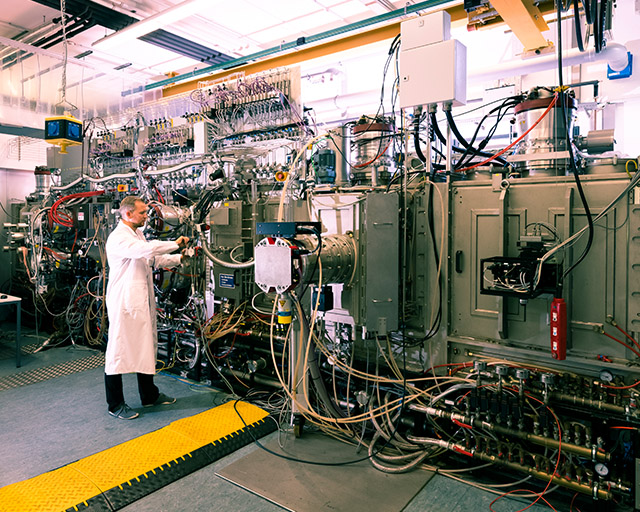

For development purposes, industrial coating facilities in batch and inline type with different source geometries (planar and cylindrical cathodes) for metallic and reactive deposition are available.

Inline coating facility for large-area coating

The experts at the Fraunhofer IST utilize the A700V inline-sputter coating facility for the research and development of coatings and complex coating systems on an industrial scale. This ranges from material and process development of single layers through to systems of up to 10 different materials, e.g. for transparent conductive oxides (TCO), low-e layer systems, electrochromics, solar protection, fuel cells, interference optics on a large area or astronomy mirrors.

Specifications / Technical data

- Inline sputtering facility with five coating modules and two lock chambers

- One lock chamber with clean-room access, incl. professional substrate cleaning system

- Planar and cylindrical sputtering cathodes as well as serial co-sputtering

- Sputtering processes: DC, RF, RF+DC, MF and HIPIM, reactive or from ceramic target

- Available gases: Ar, O2, N2, H2. Others upon request.

- Lambda probes or optical emission spectroscopy (OED) for process control

- Maximum substrate temperature 400 °C

- Substrate dimensions up to 60 x 100 cm2

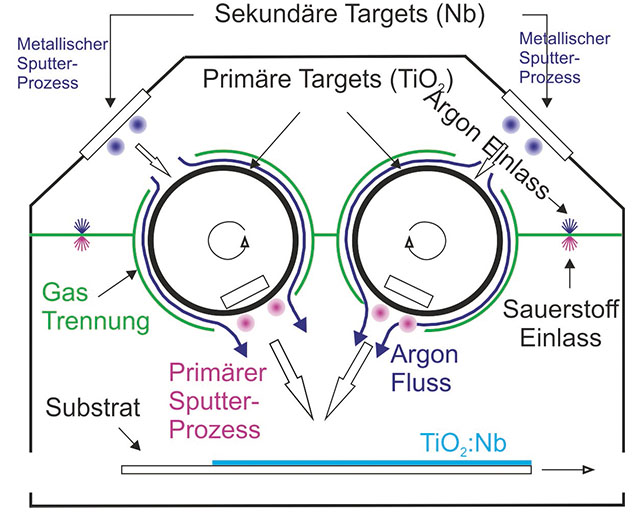

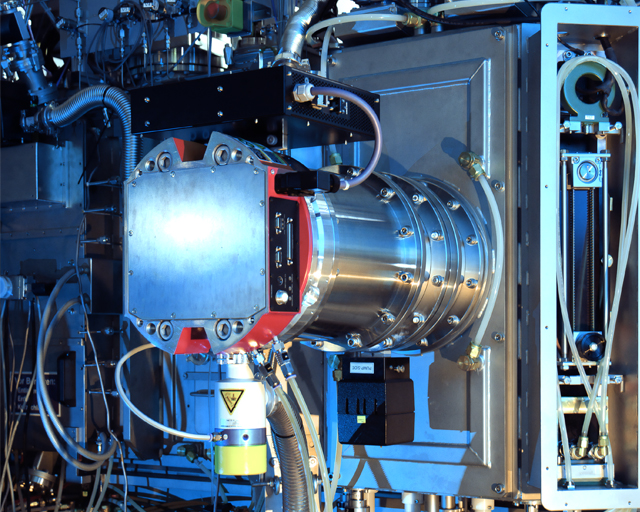

Serial co-sputtering – Megatron®

The Megatron® coating module developed at the Fraunhofer IST allows the rapid and variable realization of previously unattainable combinations of materials. Behind each of the two cylindrical tube targets, a further planar target is arranged. In the secondary sputtering process, atoms are detached from the planar target and “implanted” into the tube target. Titanium oxide, for example, can be doped with niobium and deposited. For certain material combinations, this results in an increased sputtering rate of up to 100 percent compared to the conventional process. The new module is ready for series production and can be retrofitted.

Specifications / Technical data

- Combination of two primary tube targets and two secondary planar targets

- Tube target length: 600 mm

- Cost-efficient process as a result of increased deposition rate

- Deposition of previously non-producible material combinations

- Rapid alteration of the composition of the primary tube target through variation of the performance of the secondary target

- Simple generation of gradient coatings

- Reduced development times