Transparent conductive oxides TCO

The staff of the Optical Systems and Applications department have been researching and developing transparent and simultaneously conductive materials – so-called TCOs (transparent conductive oxides) – for more than 20 years.

Their work is concentrated on the optimization of the material properties of TCOs, e.g. conductivity, light transmission and surface roughness. The focus is directed in particular at adaptation for customer-specific applications. This ranges from process and material development on small laboratory systems through to the transfer to in-line large-area deposition with controlled sputtering processes, for example for solar cells or switchable systems in the field of architectural glass coating.

Should you have any specific questions or coating requirements, please do not hesitate to contact us.

In classical TCOs, conductivity is usually generated in crystalline, transparent materials through the introduction of a doping agent. A selection of such n-conductive TCOs are:

- Indium oxide (In2O3:Sn, In2O3:Mo, In2O3:Ti, In2O3:H)

- Zinc oxide (ZnO:Al, ZnO:Ga, ZnO:Ti)

- Tin oxide (SnO2:F, SnO2:Sb, SnO2:Ta, SnO2:Nb)

- Titanium oxide (TiO2:Nb)

As a rule, we deposit such materials for the formation of a high-quality crystalline structure at elevated substrate temperature or use a process with subsequent temperature treatment, e.g. in the cases of In2O3:H (IOH) and TiO2:Nb (TNO).

A further comparatively new class is amorphous TCO materials. These are based on mixtures of two or three oxides which contain heavy metal cations with the electronic configuration (n-1)d10ns0. As a result of the outer spherical s-orbitals, these form a strongly delocalized conduction band with high charge-carrier mobility. These TCOs are characterized by good conductivity and high transmission, particularly in the near-infrared (NIR) range. Furthermore, they can be deposited at room temperature. Well-known representatives of these materials include indium zinc oxide (InZnO, IZO) and indium gallium zinc oxide (InGaZnO, IGZO).

Selected application examples for our TCO coatings

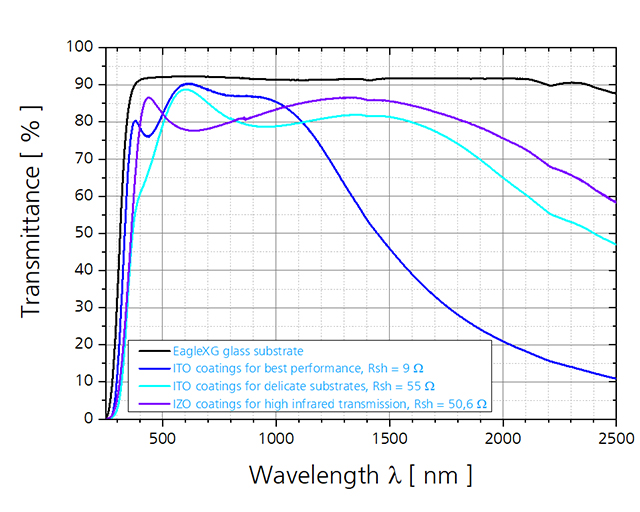

ITO coatings for the best performance

- Substrate temperature TSub = 350°C

- Specific resistance ρ = 157 µΩcm

- Layer thickness e.g. 175 nm ⇒ Tvisual ≈ 87 %, sheet resistance Rsh = 9 Ω

ITO coatings for delicate substrates

- Substrate temperature TSub = room temperature

- Specific resistance ρ = 815 µΩcm

- Layer thickness e.g. 148 nm ⇒ Tvisual ≈ 85.5 %, sheet resistance Rsh = 55 Ω

ITO coatings for ”coat and bend” processes

- Coating at room temperature with subsequent tempering

- Specific resistance ρ ≈ 300 µΩcm

- Layer thickness e.g. 140 nm ⇒ Tvisual = 86 %, sheet resistance Rsh = 21 Ω

- The substrate can be bent during the tempering process. The film does not tear (coat and bend process). The mechanical and chemical protection of the substrate is improved.

- Coating complex components such as glass tubes is possible

IZO coatings for high infrared transmission

- Substrate temperature TSub = room temperature

- Specific resistance ρ = 479 µΩcm

- Layer thickness e.g. 94.6 nm ⇒ Tvisuell ≈ 79.5 %, sheet resistance Rsh = 50.6 Ω

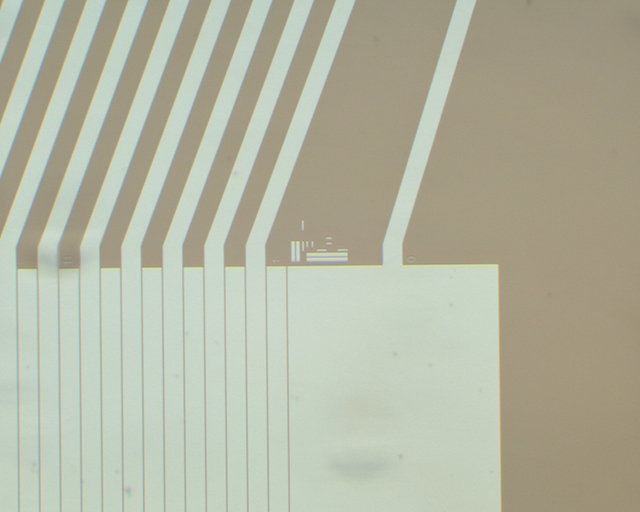

We offer research and development services for TCOs, e.g. for the following applications: structured TCOs ( by means of photolithography or laser), heating layers, switchable glasses, thin-film transistor displays (TFT), touchscreens, low-emissivity coatings (low-e), thermal-insulation coatings, light-emitting diodes (LED, OLED), solar cells, thin-film transistors, thin-glass, foil and architectural glass coatings. We would also be delighted to assist you with complete new developments.