Simulation & digital services: Simulation software for coating processes

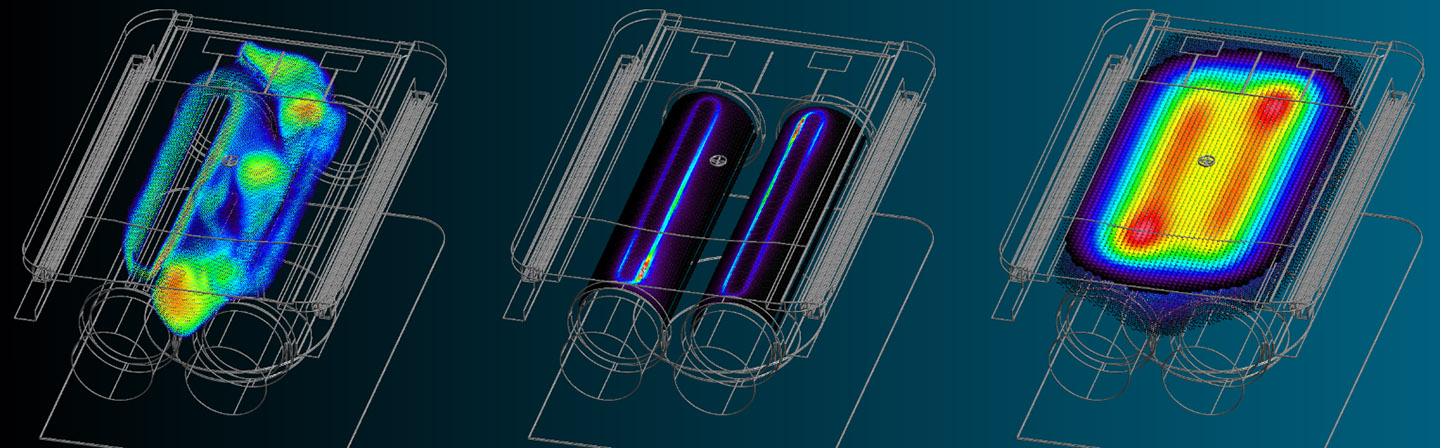

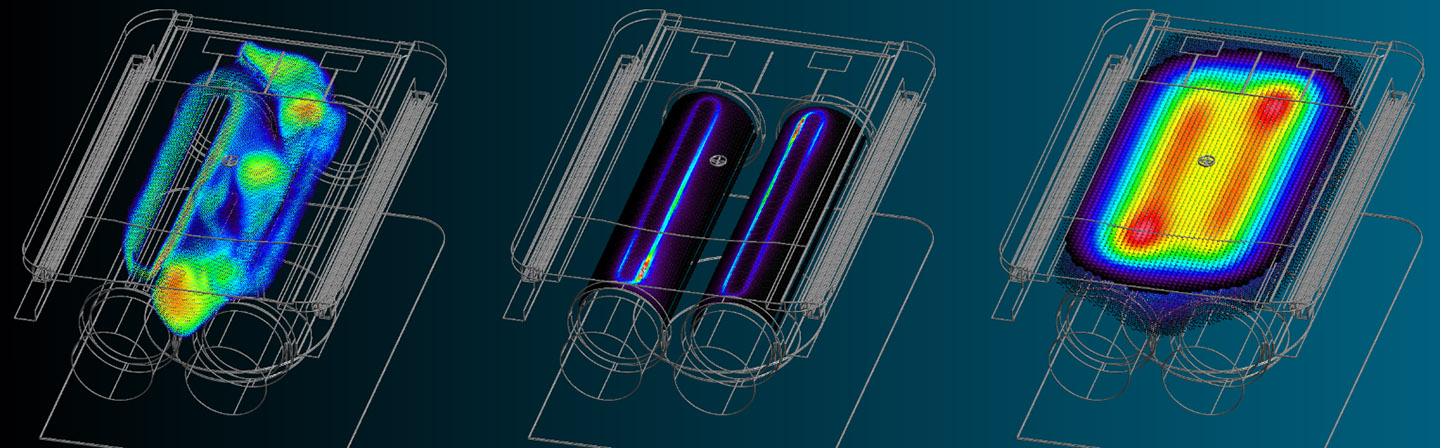

In combination with improved sensor-data acquisition, simulation of the coating process enables the exploitation of increasingly efficient and precise coating processes. As a result, the progressively increasing cost and quality requirements in thin-film technology can be fulfilled and additional information on the productivity and sustainability of process chains can be obtained.

At the Fraunhofer IST, we develop simulation software and codes in order to gain insights into the process dynamics and parameter-property relationships of coatings. Test series in process and plant development can thereby be partially substituted, enabling our customers to save time and costs. When carrying out simulation studies, we benefit from our expertise in thin-film coating technology. In addition, our extensive plant equipment enables the validation of our models. Furthermore, we are also offering know-how transfer via courses, hands-on training workshops and licensing of our simulation software.

Outlook – This is what awaits you!

Our physics-based simulation software enables a multiscale overview from the process through to the coating and product properties. With the transfer of these codes into semi-empirical models and data-driven AI approaches, we are currently working on the development of real-time-capable digital twins of coating processes. In the future, this will allow the optimization and model-based monitoring of coating processes – with minimal time expenditure. Process drifts are tracked online by the model and the prediction of required maintenance avoids unnecessary rejects and increases the overall productivity of process chains.

”Simulation enables the testing and evaluation of new processes prior to construction. Data collection and in-situ modeling form the foundation for knowledge-based process control for higher product quality and reduced waste.”

Dr. Dennis Barton / Team Manager