Determine hardness and modulus of elasticity of layers and solid materials with nanoindentation and microindentation

Nanoindentation

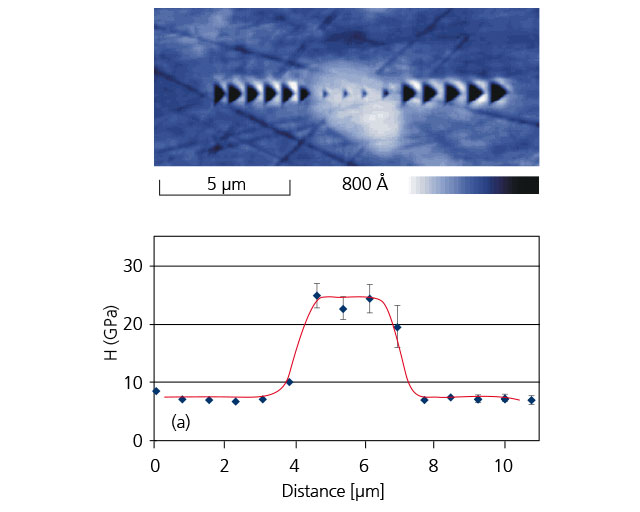

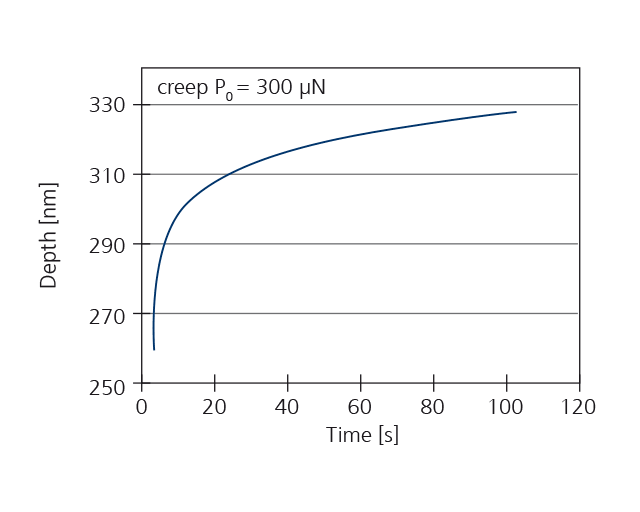

Nanoindentation allows the local determination of hardness (nanohardness) and Young's modulus on ultrathin films (> 300 nm) with a lateral resolution in the micrometer range and thus also enables local hardness measurements or hardness mapping on inhomogeneous samples. In addition, creep or relaxation tests can be used to characterize the viscoelastic properties of polymer layers or the self-healing behavior of scratches in coatings.

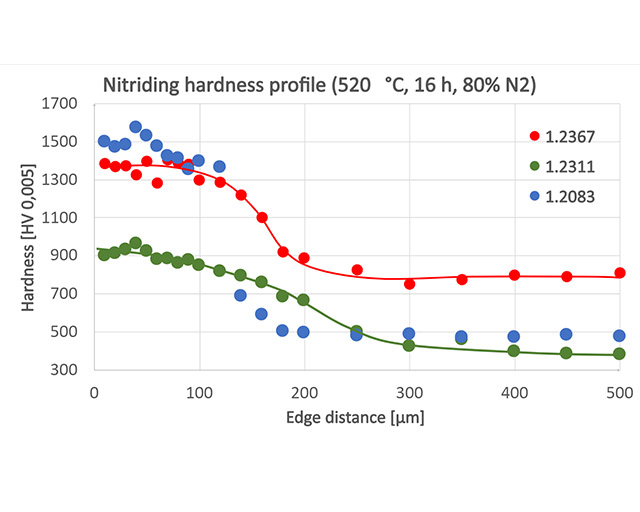

Microindentation

For thicker layers in the range > 3 µm, microindentation can be used to determine Vickers, Martens or universal hardness. Microindentation is more robust and less costly than nanoindentation. Both microindentation and nanoindentation can be used to generate hardness-depth profiles on the cross-section (e.g. for nitrided samples, multilayer systems, etc.)

Nanoindentation with high lateral resolution

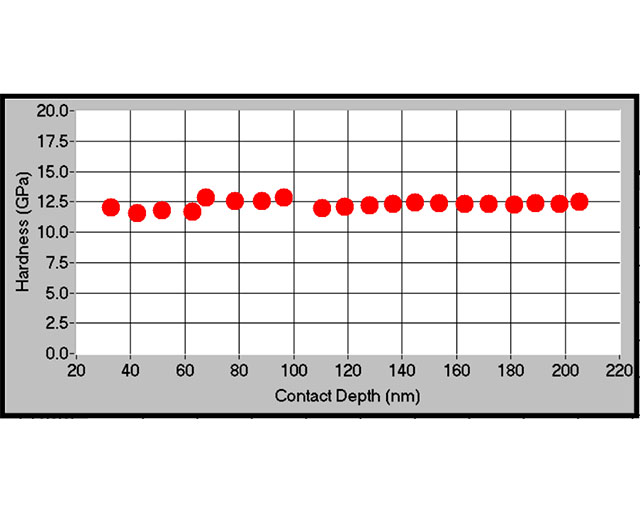

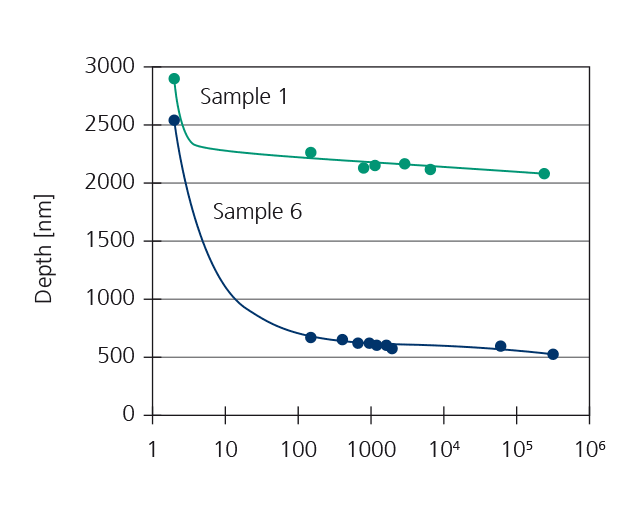

Depth-dependent hardness measurement

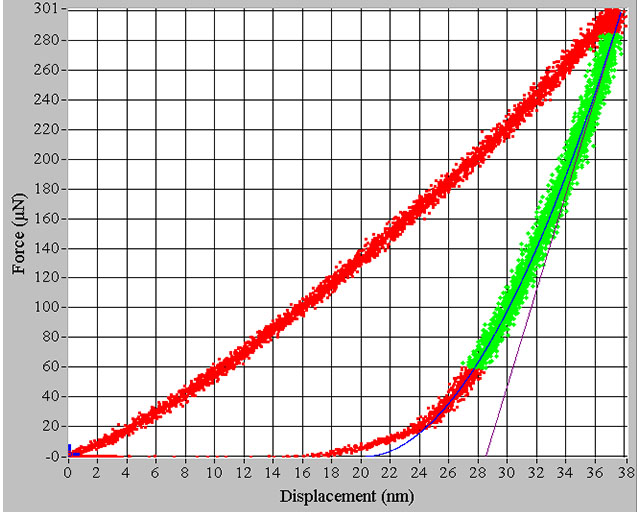

Using the multiple partial unloading technique (mpu), a depth-dependent hardness measurement can be taken directly with a single measurement, taking only approx. 1 min. This is the method of choice for deciding at what depth substrate influence becomes visible in the case of very thin layers.