Friction and wear measurement with high-load and high-temperature tribometers

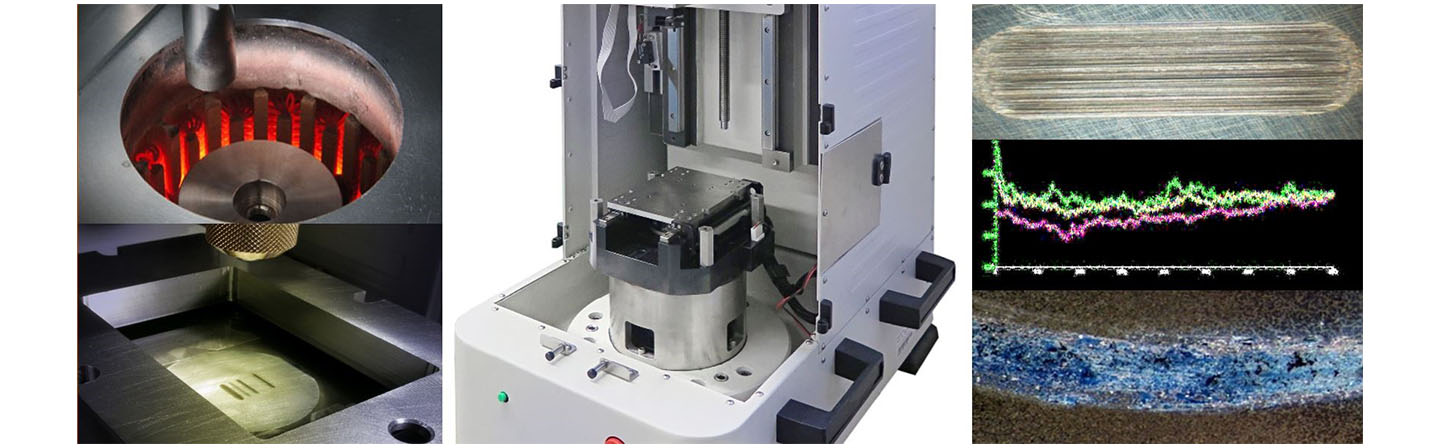

High-load and high-temperature tribometer (DIN 50324-07, ASTM G99-05, ISO 18535)

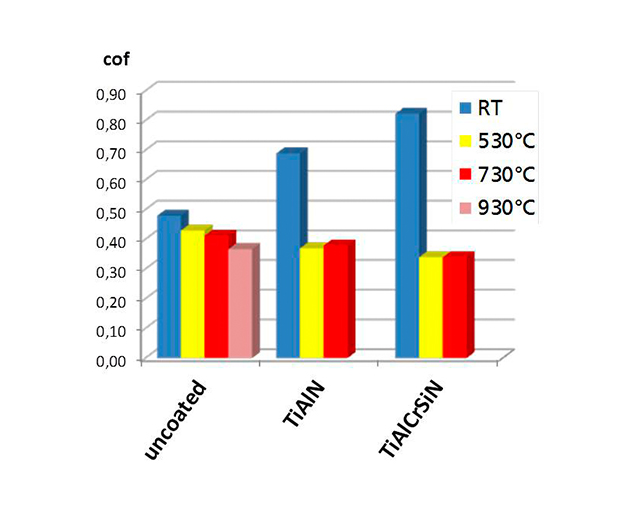

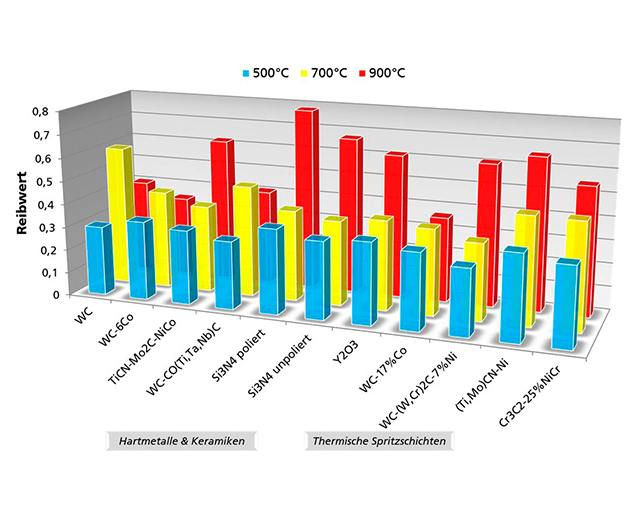

High-load tribometers and high-temperature tribometers are used to investigate the friction and wear behavior of material pairings. A test material (e.g. a steel ball) is rubbed over the sample with a defined standard force in a linear oscillating manner or along a circular path (pin-on-disk). The coefficient of friction (friction force/normal force) is measured throughout the test. The wear is determined by subsequent profilometric measurement of the wear track.

Test according to DIN 50324-1992-07, ASTM G99-05

The Fraunhofer IST has special high-temperature tribometers for test temperatures up to 1000 °C as well as high-load tribometers with normal forces in the range from 10 to 1000 N. In addition, a rolling tribometer is available in which the tribological loading of two cylinders rolling against each other (rolling friction/rolling wear) can be simulated. Investigations using liquid lubricants can also be undertaken.