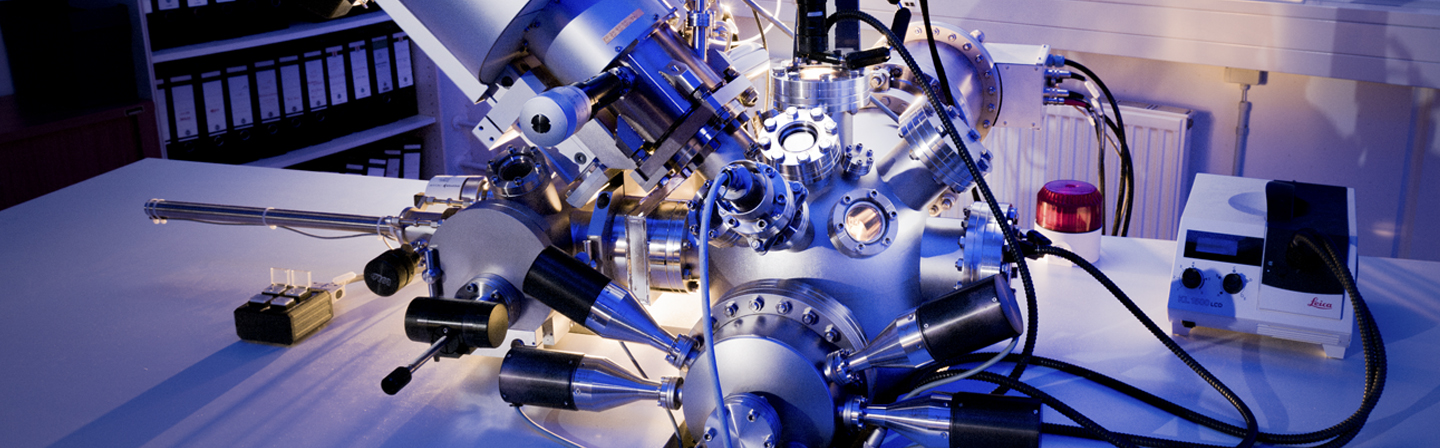

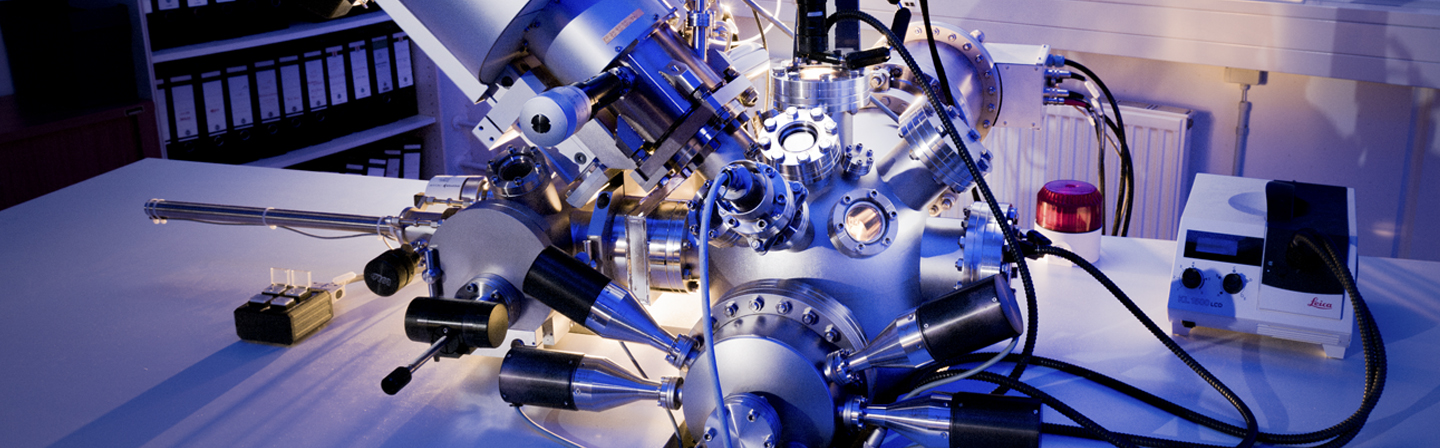

Quantitative chemical depth profile analysis using secondary ion mass spectroscopy: SIMS

How does dynamic SIMS analysis work and what can the method do?

In secondary ion mass spectrometry (SIMS), the sample surface is ablated layer by layer with an ion beam. A mass spectrometer allows the chemical characterization of the ablated material, resulting in a depth profile of the chemical composition. Technical Information:

- Detection of all elements (inc. H, Li, Be ...) and even isotopes

- Depth resolution down to 1 nm

- Lateral resolution 20 µm

- Detection of traces <1 ppm

- Depth range: 5 nm - 50 µm

Quantitative chemical depth information including of technical components

The Fraunhofer IST achieves a high quantification accuracy for secondary ion mass spectrometry (SIMS) by using special procedures. A particular strength is the quantitative depth profile analysis of hydrogen in carbon-based layers.

Further fields of application are:

- Damage analysis, coating adhesion problems, corrosion

- Quantitative concentration-depth profiles from the nano- to the micrometer scale

- Chemical investigation of interfaces, surfaces and concentration gradients

- Detection of trace elements

- Measurement of technical objects such as components and tools

We offer the analysis of various types of layers:

- Analysis of boric layers

- Analysis of nitrided layers

- Analysis of low-E coatings

- Analysis of DLC layers

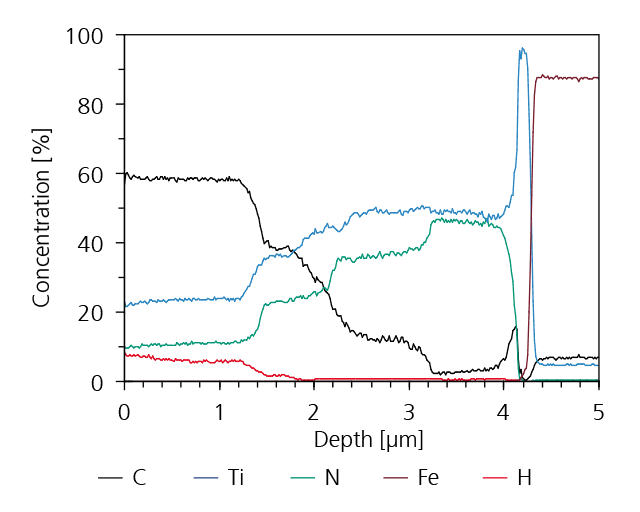

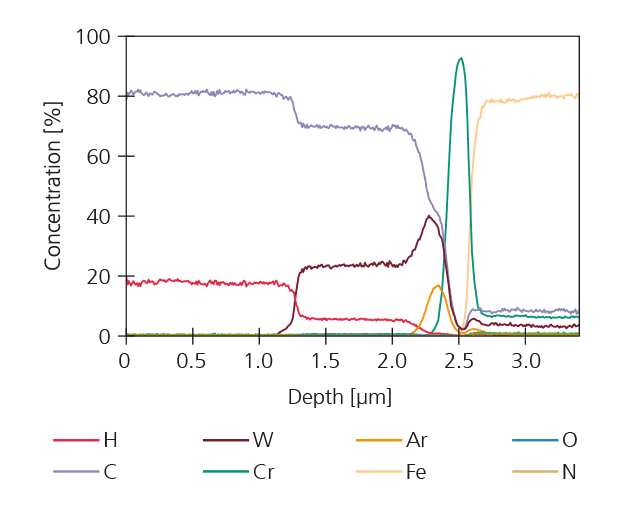

Depth profile based on secondary ion mass spectrometry (SIMS) of a wear-protection layer

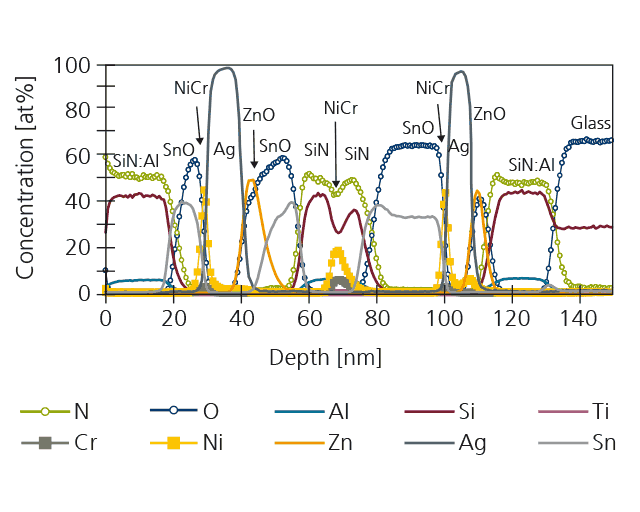

Depth profile based on secondary ion mass spectrometry (SIMS) of a thermal insulation layer on architectural glass.

Hydrogen determination in DLC layers

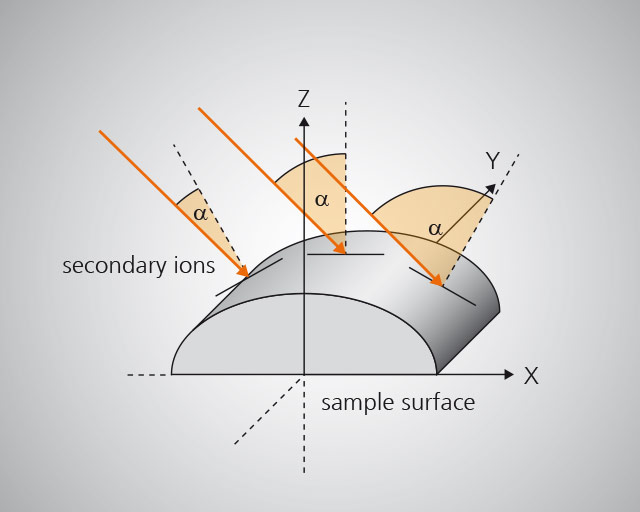

Depth profile analysis on curved surfaces

SIMS analysis can be used to quantify the depth profiles of curved surfaces. It is of particular importance to adjust the measuring position with extreme care.

More information on the depth profile analysis on curved surfaces with SIMS