Smart screw connection – Thin-film sensor reports loose screws

With the aim of realizing wireless and energy-autonomous long-term monitoring of safety-relevant structures such as bridges or wind turbines, the Research Center IoT-COMMs – part of the Fraunhofer Cluster of Excellence Cognitive Internet Technologies CCIT – had already developed the smart screw connection Q-Bo® two years ago. Q-Bo® enables regular monitoring of connections without high expenditure of time and expenses. The thin-film sensor technology developed by the Fraunhofer IST determines the pretensioning force of the screw connection and measures the ambient temperature. Q-Bo® has now been further developed by means of a new mechanical concept; as a result, commercially available DIN fasteners with a size of M18 or larger can be equipped and retrofitted with the sensor system without any major effort.

Sensor design

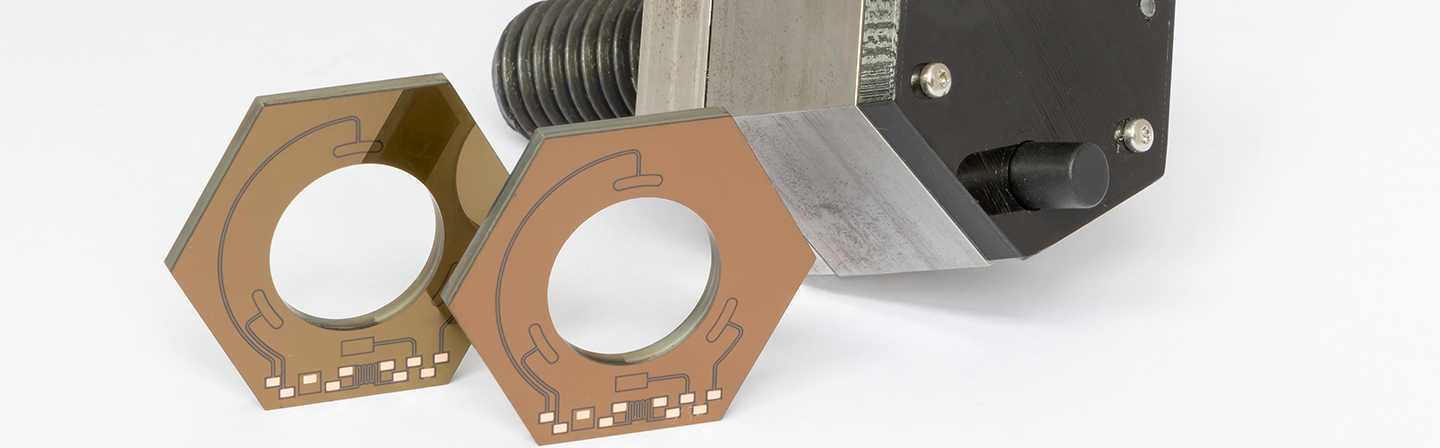

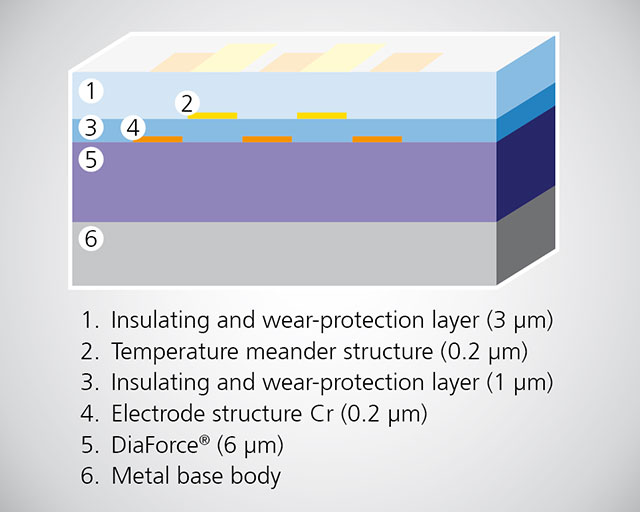

The integration of the sensor technology into the screw connection is performed at the Fraunhofer IST through the application of a thin-film system to the surface of washers. By means of PACVD processes (plasma-assisted chemical vapor deposition), the piezoresistive DiaForce® film developed at the Fraunhofer IST and the electrically insulating intermediate and top layer SICON® of the multi-sensor layer system are deposited homogeneously on the washer. The intermediate chromium electrodes form the sensor surfaces for load measurement. These structures, as well as a structure for temperature compensation and the meander structure for temperature detection, are produced in photolithographic processes in the clean room. The newly designed electrodes and conductive-paths have been specially adapted for the further-developed mechanical concept of the screw connection in order to achieve a homogeneous force distribution on the electrodes and a compact system design. Simultaneously, the optimized design exhibits improved sensor behavior.

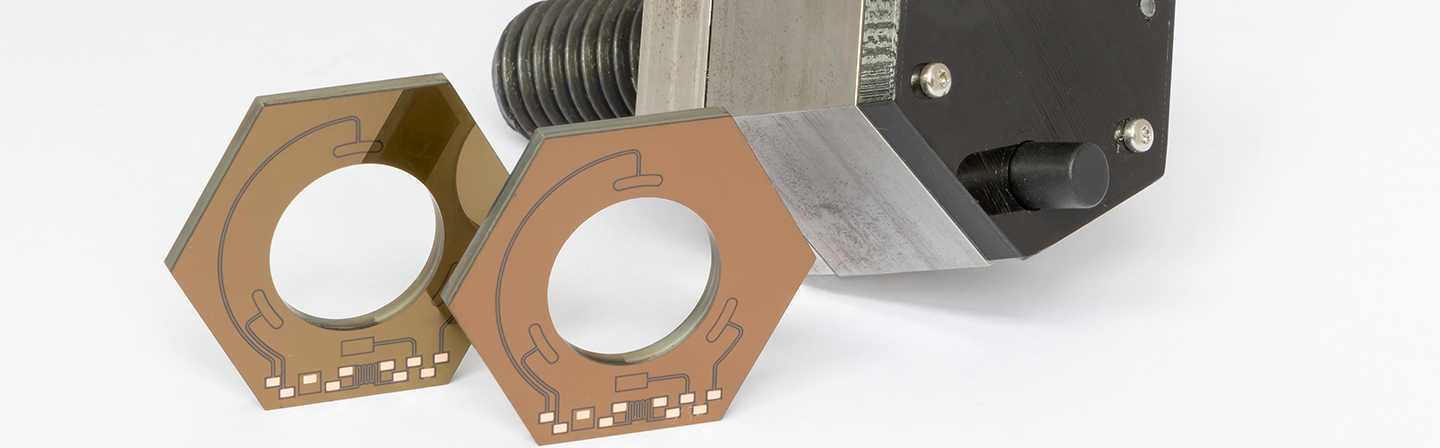

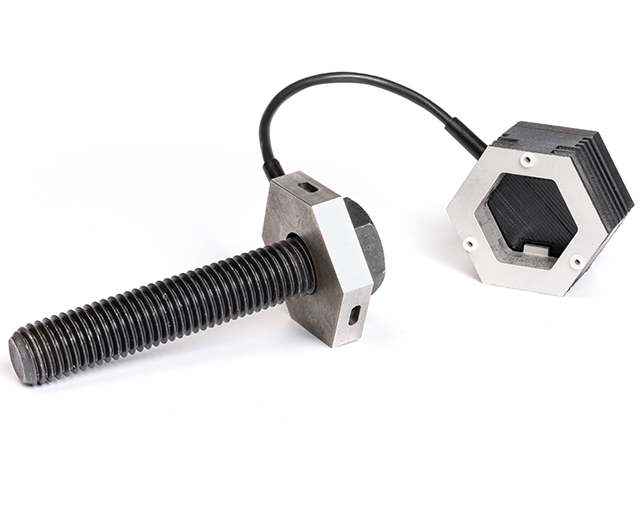

Smart screw connection Q-Bo®

The patented sensor system enables existing screw connections to be upgraded and retrofitted – using standard DIN screws from a size of M18 – for recording the pretensioning forces and the ambient temperature. The evaluation electronics are located in a cap that can be plugged onto the screw head. With the aid of the wireless transmission technology mioty®, measured values are regularly transmitted from the sensor system to a cloud-linked supervisory body. Prior to assembly, the screws are configured in the tamper-proof “FunkeyBox” programming unit and are given their own key. As a result, the sensor data is immune to attack during transmission to the base station or the backend. The autonomous energy supply is based on the energy harvesting principle and can be provided by a thermogenerator, a solar cell or a battery. In order to ensure the assembly and operational use of the Q-Bo® smart screw connection, the mechanical concept was optimized using FEM simulations, and the reliability in terms of tightness behavior and vibration resistance was validated experimentally.

Outlook

The project results obtained are to be used for the application-oriented optimization of the Q-Bo® smart screw connection. For this purpose, potential users, such as manufacturers and operators of wind turbines, trains, cranes or construction machinery, will be provided with so-called evaluation kits (currently in the sizes M18, M20, M30 and M36).

The project

This patented solution is being developed within the framework of the Fraunhofer Research Center IoT-COMMs in collaboration with the Fraunhofer Institutes IST, IIS, LBF and AISEC. The FIoT-COMMs is part of the Fraunhofer-Gesellschaft’s cluster initiative CCIT (Cluster of Excellence Cognitive Internet Technologies).