Interfacial chemistry and adaptive adhesion

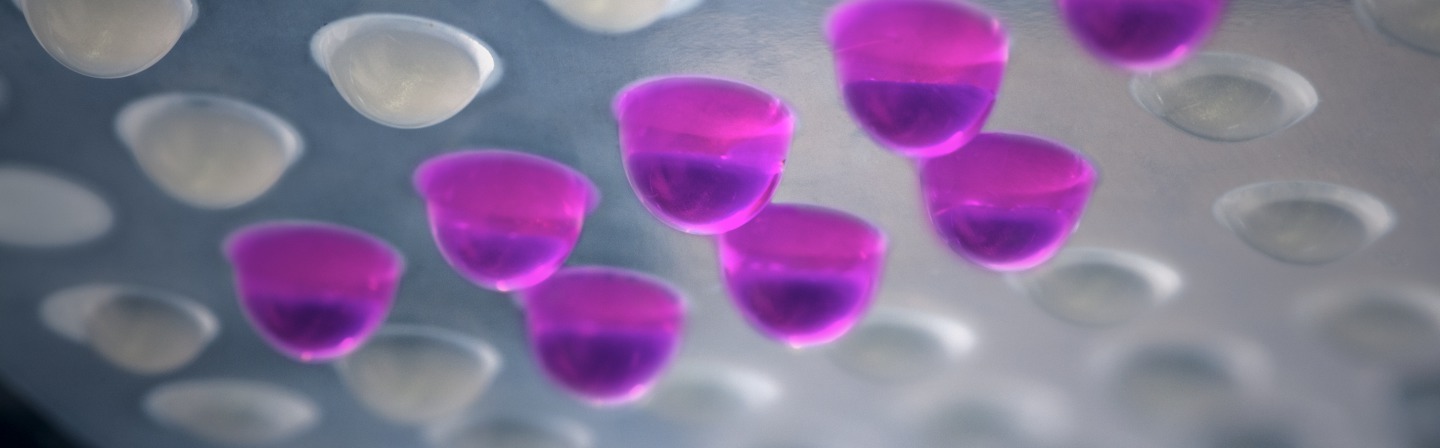

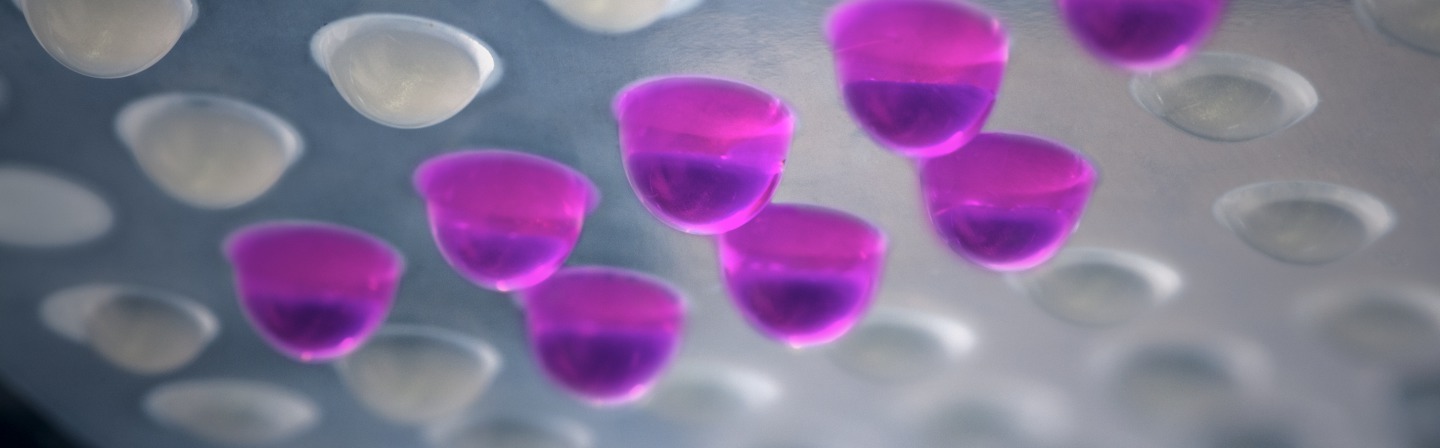

For the defined wetting of surfaces and the targeted control of adhesion, e.g. of coatings, adhesives and biomolecules, or in the case of delamination in recycling processes, the optimum design of the interface is a critical success factor and a key to innovations. In the production of widely differing goods, quality requirements and specifications are high and, as in e. g. medical and pharmaceutical technology, lead to intense pressure as regards innovation and cost-effectiveness. The nature of the interfaces often determines the functionality, durability, recyclability and, ultimately, the quality of a product.

At the Fraunhofer IST, we are working on solutions for product and production systems which have one thing in common: an optimum interface. We deploy our extensive expertise in the pretreatment and coating of complex surfaces as well as industry-oriented and sustainable electrochemical processes and atmospheric-pressure plasmas in order to develop an optimal process chain for our customers. On the basis of our modular process concept with a focus on sustainable and resource-saving technologies, process-associated analytics, and with the aid of simulation methods, we develop the appropriate system solution for individual problems. For the validation of the results, we have an extensive portfolio of surface-analysis methods at our disposal. As a result, sustainable products are created along the entire value chain, from the development stage through to recycling.

”The adhesion of many material combinations can be significantly increased through an optimal interface. For many products, the range of applications can thereby be expanded, and the functionality and long-term stability can be improved.”

Prof. Dr. Michael Thomas, Head of Department