BALU consortia project develops production technologies for low-cost and safe aluminum-ion batteries

In the joint project “BALU - Production technology for battery cell concepts on the basis of aluminum-ion technology”, a consortium of research institutions and specialized industrial companies is further developing the aluminum-graphite dual-ion battery (AGDIB). As a result of its high power density, AGDIB technology has tremendous potential in the area of highly dynamic load requirements and could be an alternative to cost- and material-intensive lithium batteries. The project is pursuing the ambitious goal of transferring the production of AGDIB cells from laboratory scale to industry-compatible production conditions. In addition to the transfer of the new battery technology, explicit ecological considerations – such as environmentally friendly production, subsequent recycling, and the avoidance of critical raw materials – hereby play an important role. The BALU project is funded by the German Federal Ministry of Education and Research (BMBF) within the framework of the “Batterie2020Transfer” program.

Too good to be true?

It would be a technological breakthrough: inexpensive, powerful, rechargeable batteries, with no critical raw resources or flammable materials, easy to manufacture, safe to operate and simple to recycle after years of use.

A new technology with the somewhat cumbersome name “aluminum-graphite dual-ion battery”, AGDIB for short, could actually make this possible. In the laboratories of the Fraunhofer THM in Freiberg, prototypes already exist that have demonstrated the potential of the cell chemistry in extensive test series. With its high power density, the AGDIB would be particularly suitable for highly dynamic load requirements, in which the cost-intensive lithium titanium oxide (LTO) technology has been the state-of-the-art up until now.

The decisive factor for such applications is the highest possible charging rate. The higher the charging rate, the faster the cells can be charged and discharged. Tests with flexible AGDIB pouch cells have shown that long-term stable operation is possible at very high rates of over 30 C - a very good value for this cell format. The other electrical parameters and the cycle stability can also match the performance of expensive LTO batteries. In contrast to LTO technology, however, the AGDIB uses non-toxic, inexpensive and readily available materials.

Out of the lab!

The design of the laboratory samples is nevertheless not yet suitable for series production; before a transfer to mass production can be enabled, completely new development tasks must be addressed. This concerns both the production of the utilized materials and the individual cell components as well as the design and manufacture of the entire AGDIB cell.

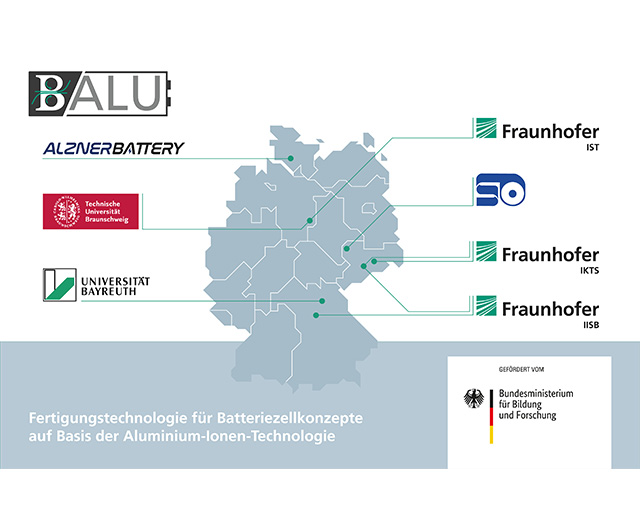

Motivated by the promising test results, a consortium comprised of research institutions and specialized industrial companies has now come together to take the next decisive steps towards market maturity. Under the umbrella of the BMBF joint project “BALU - Production technology for battery cell concepts on the basis of aluminum-ion technology”, partners from various specialist areas are contributing their expertise and jointly driving forward the development of the AGDIB.

As the name of the project suggests, the ambitious objective is to transfer the production of AGDIB cells from laboratory scale to industry-compatible production conditions. Economical roll-to-roll processes are thereby coming to the fore in order to be able to produce large quantities of multilayer pouch cells.

As soon as the AGDIB pouch cells are available in sufficient quantities, the project partners can build complete battery modules, specify the operating behavior of the cells and define the parameters for the system design. The AGDIB high-performance modules will then be integrated into industrial battery systems and will have to prove their quality in practical operation. The focus here is on specific applications, such as electrical power boosters for large appliances or stationary storage systems for power-grid stabilization.

Taking batteries a step further

In the further development of the AGDIB, not only electrical performance capability and production technology play a role, but also economic and ecological considerations. The global demand for electrical energy storage systems is increasing constantly and the advancing electrification requires an ever-greater amount of resources. With the increasing utilization of batteries, questions regarding the materials used, environmentally friendly production and operational safety as well as subsequent recycling are becoming all the more important.

All of this must be taken into account at the earliest possible stage of the technological development. In this respect, the BALU consortium brings together extensive expertise in the fields of materials research, production technology, battery system technology and life cycle assessment. In addition to possibilities for the substitution of critical raw materials, the project partners are investigating each and every step from cell and module design through to system integration with regard to their recycling-optimized design, and are examining the entire product life cycle from a holistic perspective.

The search for alternative material systems is particularly worthwhile with regard to the cost-intensive LTO battery cells. For highly dynamic applications, the energy content of a battery is not the primary factor, but rather the fastest possible provision of electrical power. This is where the aluminum-graphite dual-ion battery has enormous potential. It combines economic advantages and environmental aspects.

About the consortium partners

Fraunhofer IISB

The Fraunhofer Institute for Integrated Systems and Device Technology IISB in Erlangen specializes in wide-bandgap semiconductors and efficient power electronics. At its branch in Freiberg, the Fraunhofer Technology Center High Performance Materials THM, the Fraunhofer IISB is working in collaboration with the Fraunhofer IKTS on sustainable battery systems with improved eco-balance and raw-material availability. In the BALU project, the Fraunhofer IISB has the role of project coordinator and is evaluating the active and passive components for the AGDIB cells, including the cell housings. In addition, it is developing and characterizing cost-effective, long-term-stable AGDIB cell concepts as well as functional demonstrators for AGDIB pouch cells.

Fraunhofer IKTS

The Fraunhofer Institute for Ceramic Technologies and Systems IKTS in Dresden conducts application-oriented research into high-performance ceramics: from materials, through manufacturing processes, and on to pilot systems. The portfolio is supplemented by materials diagnostics and testing. In the BALU project, the Fraunhofer IKTS is developing recycling-friendly cell concepts for AGDIB technology using industry-relevant manufacturing technologies. The IKTS is also creating the demonstrator cells for the “proof of concept” of various AGDIB cell designs.

Fraunhofer IST

The Fraunhofer Institute for Surface Engineering and Thin Films IST in Braunschweig develops technologies in the field of surface modification, structuring and coating for sustainable products and the associated scalable production systems. This is also carried out with a view to closed material and substance cycles. In the BALU project, the Fraunhofer IST is undertaking the development of a cost-effective, corrosion-resistant current-collector material for AGDIB cell chemistry as well as a technology for the long-term-stable and airtight sealing of AGDIB pouch cells.

University of Bayreuth / SysEE und LEEE

The Chair of Systems Engineering for Electrical Energy Storage (SysEE) at the University of Bayreuth researches the interaction between cell, mechanical structure, thermal management, electronics and software. With its integrative character, the SysEE is the ideal partner for the Chair of Electronics for Electrical Energy Storage (LEEE), which is also based at the University of Bayreuth. The LEEE is working on solutions for the electronic monitoring and control of electrical energy storage systems such as batteries, supercaps and fuel cells. In the BALU project, the two chairs are investigating the specific behavior of AGDIB pouch cells in use as well as the specific requirements for the system design. In addition, the electrical characterization of various topologies for AGDIB module interconnections is being performed.

TU Braunschweig / IWF

The Chair of Sustainable Manufacturing & Life Cycle Engineering at the Institute of Machine Tools and Production Technology IWF at the TU Braunschweig analyzes and evaluates industrial production and recycling process chains from an economic, ecological and simulative-technological perspective. In the BALU project, the IWF is undertaking the life cycle assessment (LCA), cost estimation and environmental balancing for the AGDIB pouch-cell technology, including the utilized materials and manufacturing processes.

Sika Werke GmbH

Sika Werke GmbH in Leipzig is a specialist in the production of composite films using the dry-lamination process as well as in the field of packaging and coating of metal and plastic films. In the BALU project, Sika is developing production technologies for corrosion-resistant, recyclable composite films and for the encapsulation of AGDIB pouch cells.

Alzner Battery

The medium-sized company Alzner Automotive GmbH, based in Grafenau, began processing metal for the automotive industry in 2004. Since 2020, the new Alzner Battery division in Itzehoe has been developing and manufacturing high-performance battery systems for stationary, mobile and industrial applications. In the BALU project, Alzner Battery is evaluating the performance capability of the AGDIB in newly constructed demonstrator modules and comparing them with established lithium-titanium oxide battery technology.

The consortia project BALU is founded by the Federal Ministry of Education and Research (BMBF) as part of the "Batterie2020Transfer" program.

Last modified: