Data acquisition and model based process optimization

From raw material to high-tech product with innovative process, process and production technology

At the Fraunhofer Institute for Surface Engineering and Thin Films IST, we keep an eye on the entire product life cycle and develop sustainable products and associated production systems. Model-based process optimization plays a central role in this. Digitization, networking and automation are the keys to a holistic design of process chains and their embedding in production systems. Central to our work is a profound understanding of the relationships between the process parameters, the resulting structure of thin films and surfaces, and the final properties of the product. Inline and laboratory analytics create the foundation for this and provide important data for simulation-based approaches, e.g. for a simulation of layer growth or new data-driven approaches based on machine learning.

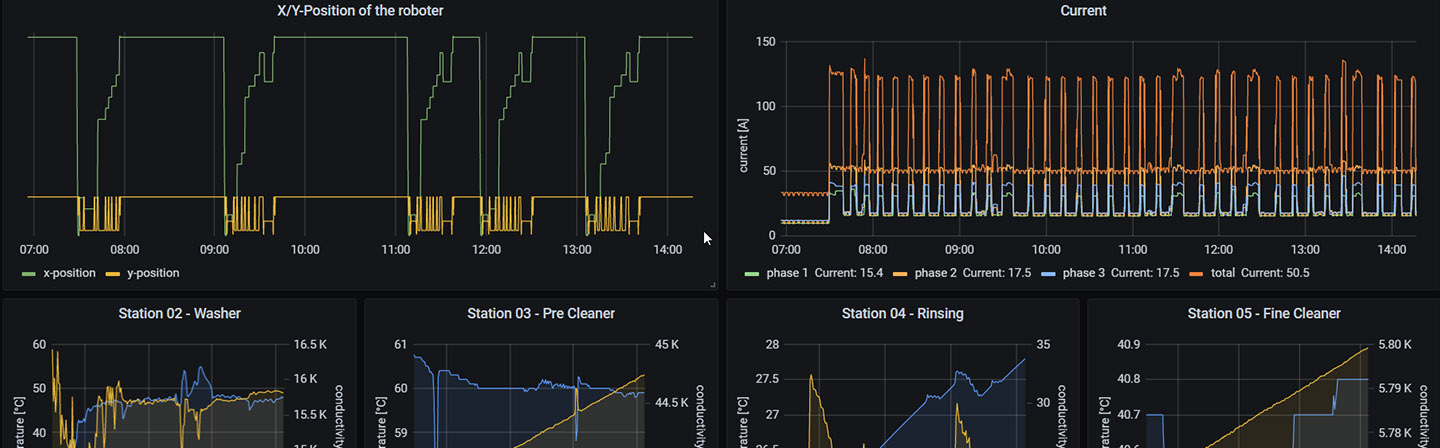

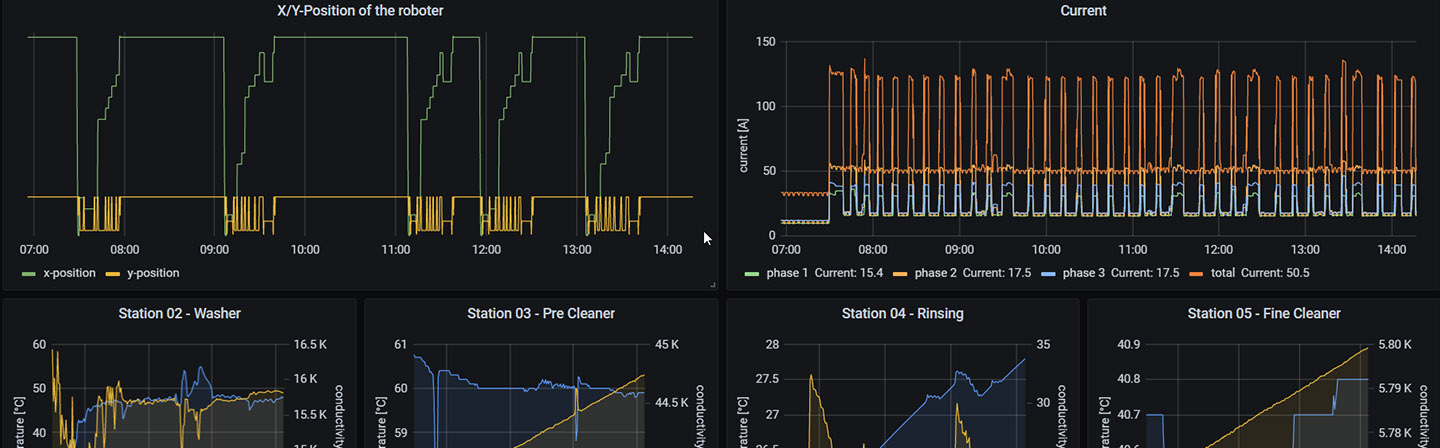

The process chain for the production process starts with the pre-treatment. This can be dry cleaning with atmospheric pressure plasma or wet-chemical cleaning in a modular cleaning system with integrated water treatment. Our cleaning processes also have a digital twin, on the basis of which the processes are further optimized. After cleaning, the coating process takes place. Depending on the application, we have extensive system technology at our disposal in various scaling levels.

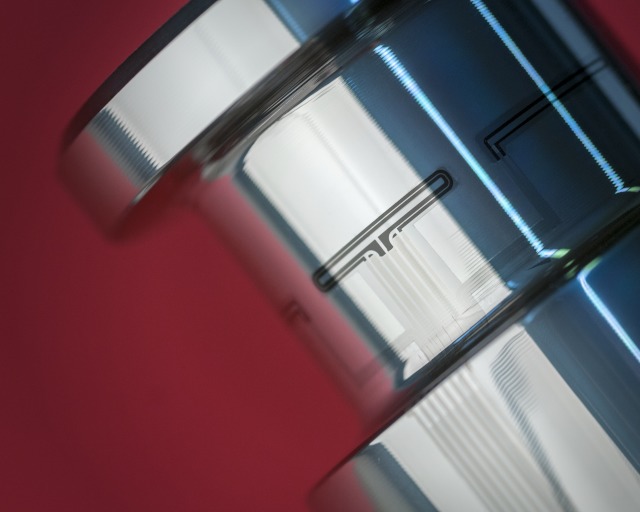

This includes, for example, industrial plasma coating systems and electroplating, such as those used for the production of wear protection layers, systems for atomic layer deposition and systems developed in-house such as the EOSS® coating platform for the production of precision-optical or highly conformal coatings, hot-wire CVD coating systems for the production of silicon and diamond layers as well as systems for atmospheric pressure plasma treatment for the production of adhesive and anti-adhesive layers.

With digital twins, which we develop for various systems, it is possible to optimize the processes in advance. Our inline monitoring system MOCCA+® provides data for automated process control and monitoring. An accompanying analysis ensures product quality and provides additional data for model-based process optimization.

We think of digitization holistically: From the material to the process chain to recycling, we plan sustainable factories. The goal is the sustainable production of high-tech end products such as a smart king pin, which forms the connection between the tractor and semitrailer on the truck. Thanks to our integrated thin-film sensors, it increases safety and reduces fuel consumption. Another example are process chains for energy storage and in particular batteries and components for hydrogen applications. Another example is the development of so-called green tools, which are sustainable high-performance tools adapted to the application. Here we work together with our partners at universities and in particular the institutes from the Fraunhofer Group for Production.